Other installations

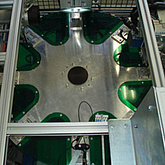

HeatShield installation

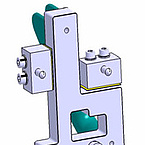

Prior to the leak test, a heat shield is installed. To do this, the tank and shield are manually inserted and clamped into a vertical rotary table’s clamping device. The heat shield is screwed into place using a pneumatic screw driver and four screws located at two screw points. The plant is secured by an electronic key system.

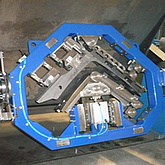

Device for gluing in place boot trim panels

The boot’s side trim panels are covered with acoustic dampers. For this purpose, the side parts are placed on the device with the visible side facing down and fixed in place. The device consists of fibre-glass-reinforced plastic. The trim panel can only be inserted in one direction. It can neither fall out nor slip (poka-yoke).